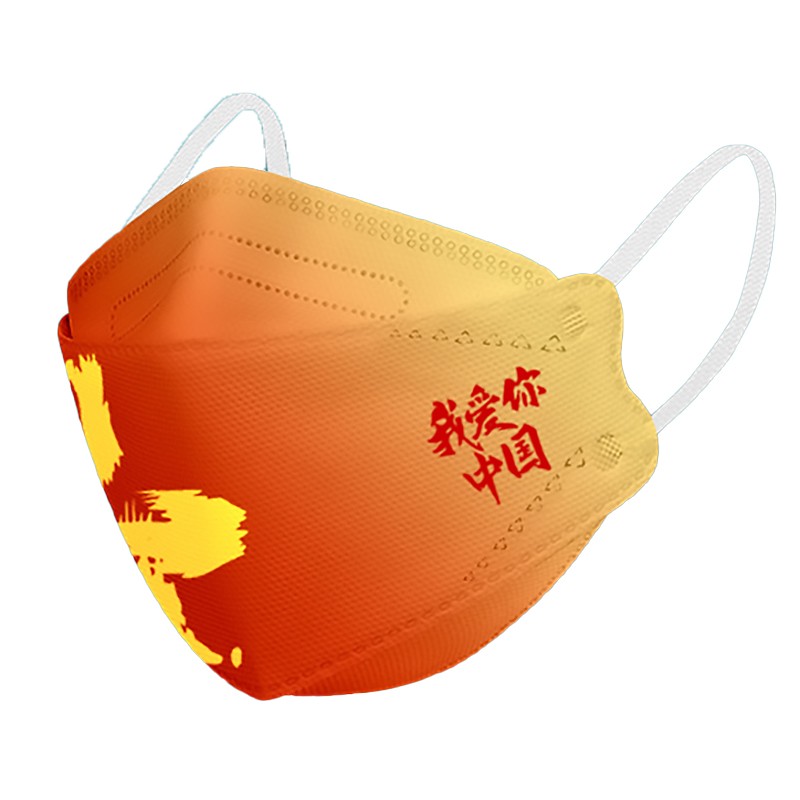

The machine is mainly used for the production of fish masks with printed patterns on the surface, and the patterns have position requirements. The printing pattern is precisely positioned to the designated position of the mask through the servo-driven positioning mode. The whole machine is servo design, easy to operate, stable and efficient.

Equipment features:

A. Full servo design. The welding ear structure adopts full servo design, reducing the use of gas, and the equipment is more high-speed, stable and low noise.

B. High steel structure. Sliding parts all use linear guide structure, equipment rigidity is better, more stable.

C. Blow your ears. Blowing cold folding structure, folding ear effect is better, reduce gas consumption, energy saving and high efficiency.

D. Automatic correction. Configuration of automatic correction mechanism, fabric running more accurate, more stable production.

Production rate | 100~130 tablets/min |

Product size (mm) | According to customer requirements |

Device shape (mm) | 5400x3300x1600 |

Machine weight | Approx. 1500Kg |

Electricity demand | AC 220v/50Hz Rated power 15Kw |

Gas requirement |

Established industry university research and development cooperation with well-known domestic universities such as the Chinese Academy of Sciences, the University of Hong Kong, Soochow University, and Zhengzhou Institute of Technology

The factory has introduced modern management systems such as OA, CRM, and ERP for digital informatization, scientific management, efficient and high-quality production, and reduced labor and time

Famous domestic and foreign brand components, lean production management, full inspection and certification of quality, strictly following the ISO 9001 production quality management system

Professional engineer service support, industry technical elites quickly solve your needs, providing customers with a professional, fast, and superior service experience.