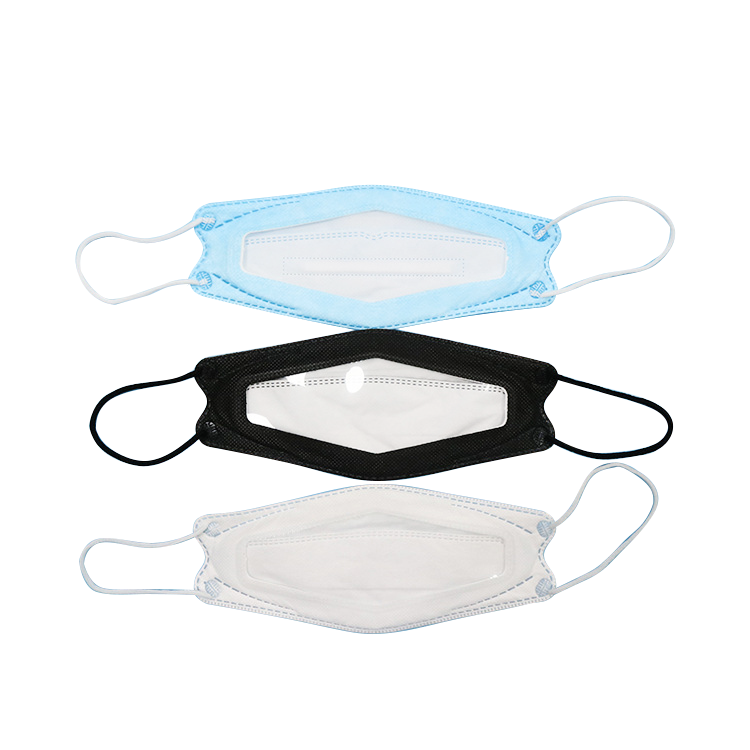

This machine is mainly used for the production of window masks for special people (deaf and mute), which can realize the automatic completion of the whole process of window opening, slicing, patch and welding, full servo control, accurate window position and solid welding. The operation of the whole machine is coordinated, stable and efficient.

Equipment features:

A. Full servo design. The window opening, slicing, welding and other processes are fully servo controlled, the window position is accurate, and the welding is firm.

B. Save materials. Film cutting and conveying are controlled by motion to minimize the loss of transparent film.

C. Automatic correction. Automatic correction mechanism is configured to prevent deviation of cutting and welding Windows.

D. Customize functions. Clear face mask to meet the needs of people with hearing impairment who can read lips.

Production rate | 80~100 tablets/minute |

Product size (mm) | According to customer requirements |

Device shape (mm) | 5400x3300x1600 |

Machine weight | Approx. 2300Kg |

Electricity demand | AC 220v/50Hz Rated power 15Kw |

Gas requirement |

Established industry university research and development cooperation with well-known domestic universities such as the Chinese Academy of Sciences, the University of Hong Kong, Soochow University, and Zhengzhou Institute of Technology

The factory has introduced modern management systems such as OA, CRM, and ERP for digital informatization, scientific management, efficient and high-quality production, and reduced labor and time

Famous domestic and foreign brand components, lean production management, full inspection and certification of quality, strictly following the ISO 9001 production quality management system

Professional engineer service support, industry technical elites quickly solve your needs, providing customers with a professional, fast, and superior service experience.