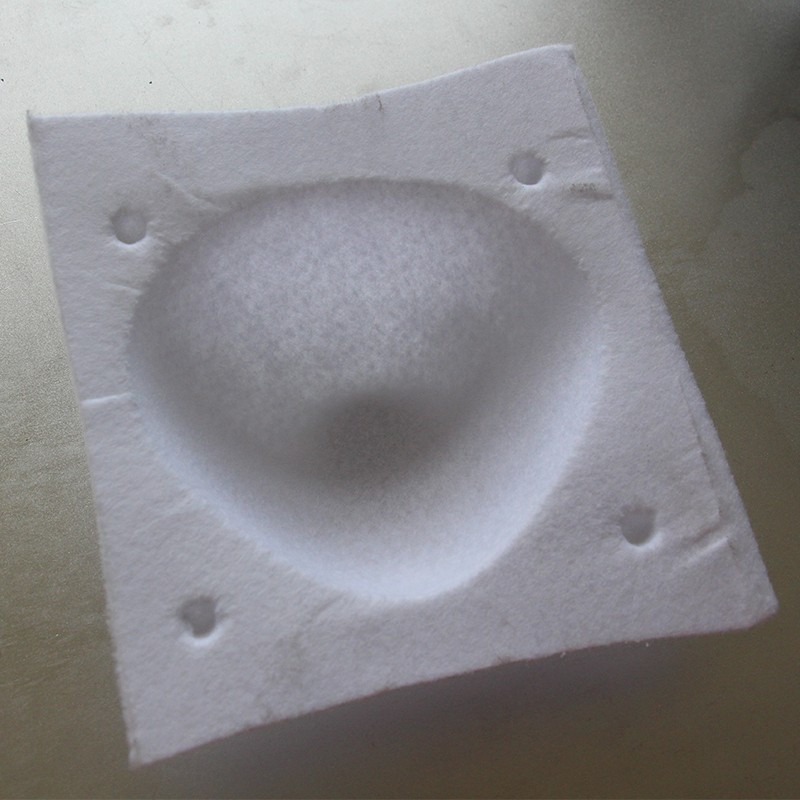

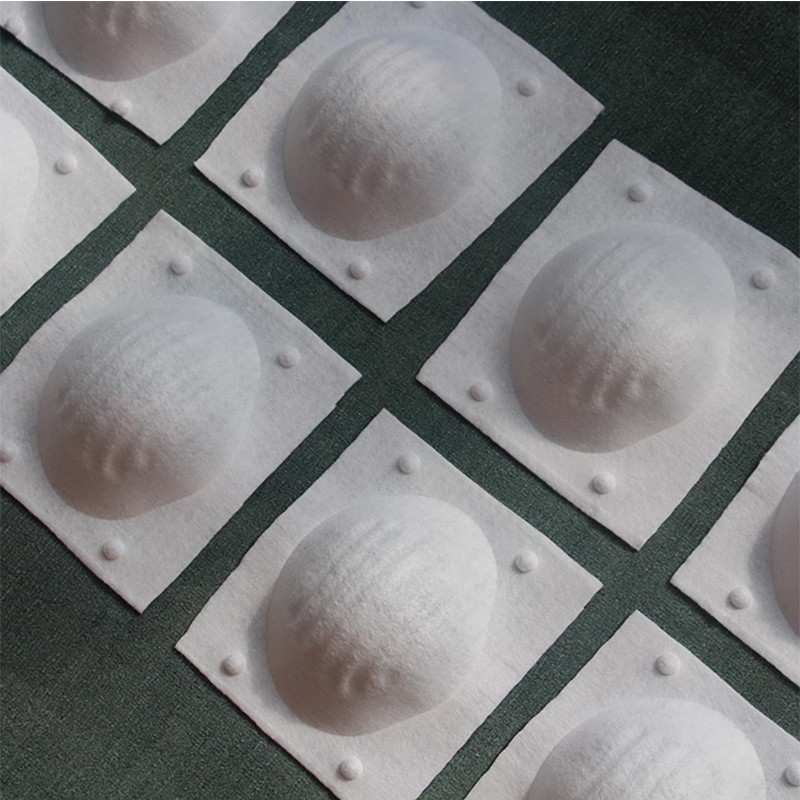

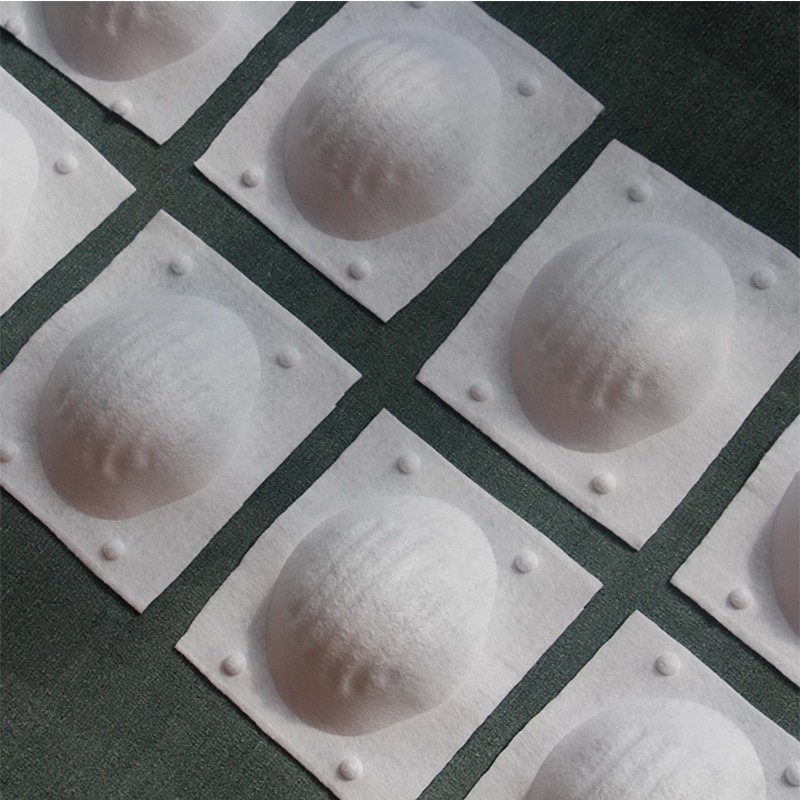

Automatic cup-shaped mask shaping cutting and stacking machine is a cup-shaped mask shaping equipment developed by Lihan Company, which is suitable for customers to produce various types of cup-shaped masks and choose automatic equipment. The machine has the functions of automatic feeding, automatic pulling, automatic cutting, automatic stacking, etc. This machine is based on the principle of constant temperature and hot pressure setting, after forming the mask shape full, beautiful appearance, clear embossing; PLC program control, automatic operation of the whole machine.

Equipment features:

1. Program control, servo feeding, constant temperature setting, automatic cutting, automatic stacking;

2. The quality of the masks produced is stable, in line with the quality testing standards of masks, and the efficiency is increased, saving labor;

3. Stable operation of the equipment, with long-term continuous operation;

4. Automatic equipment control, smooth operation, stable product production, good quality;

5. Mature process, stable quality, high efficiency.

Production rate | 60 tablets per minute |

Product size (mm) | According to customer requirements |

Device shape (mm) | 3000mm*1500mm*1800mm |

Machine weight | About 2000Kg |

Electricity demand | AC 220v/50Hz Rated power 8Kw |

Gas requirement | 0.3-0.7 MPa |

Established industry university research and development cooperation with well-known domestic universities such as the Chinese Academy of Sciences, the University of Hong Kong, Soochow University, and Zhengzhou Institute of Technology

The factory has introduced modern management systems such as OA, CRM, and ERP for digital informatization, scientific management, efficient and high-quality production, and reduced labor and time

Famous domestic and foreign brand components, lean production management, full inspection and certification of quality, strictly following the ISO 9001 production quality management system

Professional engineer service support, industry technical elites quickly solve your needs, providing customers with a professional, fast, and superior service experience.